The 48th International Exhibition of Inventions of Geneva was held from April 26th to 30th in Geneva, Switzerland. Three patented technologies developed by the National Engineering Research Center of High-speed Railway Construction Technology and a research team from the School of Civil Engineering at CSU were exhibited at the event. Among them, the “Seismic Safety Test System for Trains Running on High-Speed Railway Bridges Under Earthquakes” won the gold medal. The two technologies, “Laser Profile Scanning-based Track Irregularity Measurement Device and Method” and the “Real-time Simulation Test System for High-Speed Railway Trains Running under Earthquake Action”, won the silver medal.

The International Exhibition of Inventions of Geneva was founded in 1973 and is jointly organized by the Swiss Federal Government, the Geneva State Government, the Geneva City Government, and the World Intellectual Property Organization. It is one of the longest-running and largest invention exhibitions in the world, with one event held annually. The exhibition attracted more than 1,000 invention projects from over 40 countries, and the 165 Chinese invention projects exhibited have received great attention. Among them, 55 projects won gold medals.

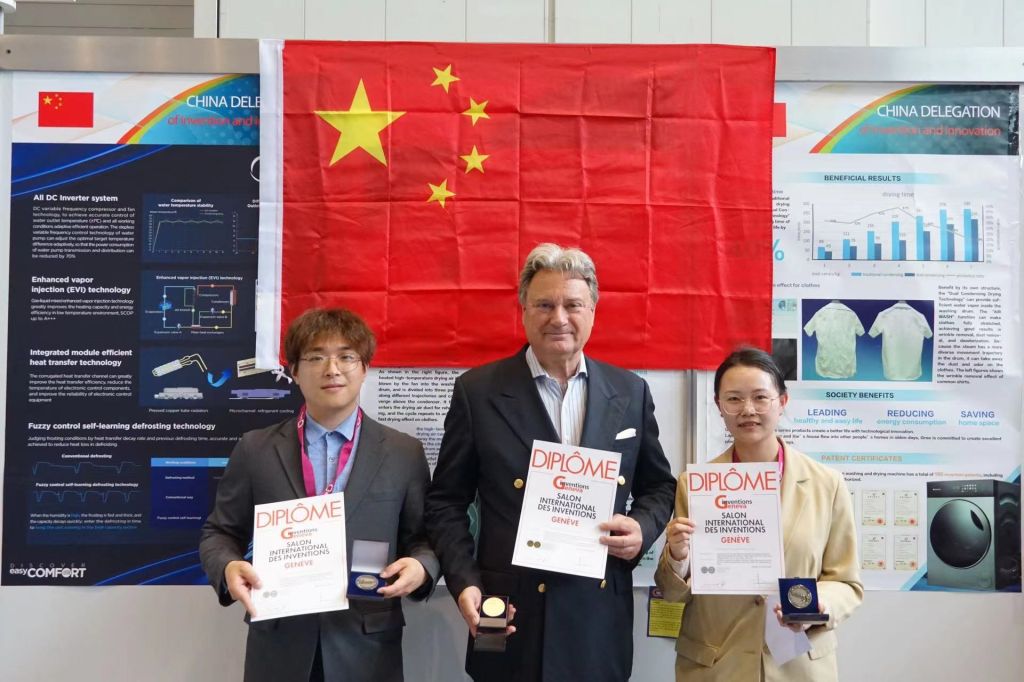

Tachi, chairman of the evaluation committee (center), presents the awards to the laureates for their patented technologies

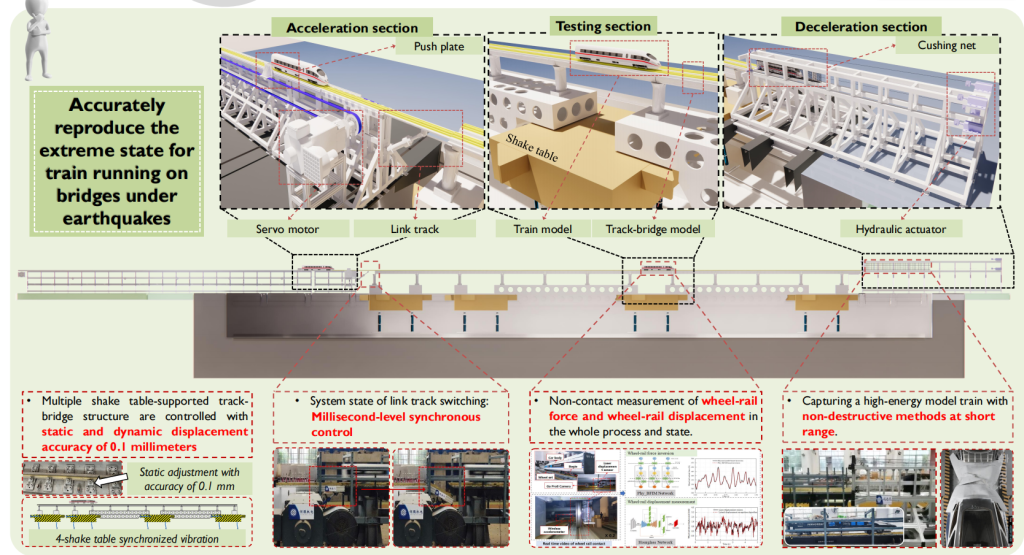

China’s high-speed railway network passes through many seismic zones, and ensuring the safety of trains running on bridges under earthquakes is a major requirement for high-speed railway construction and sustainable development. Due to the suddenness, destructiveness, and unpredictability of earthquakes, there is a lack of high-speed rail seismic damage records worldwide, and there is no indoor test method and scientific experimental evidence for the earthquake-induced derailment of trains. The seismic safety testing technology and system for trains running on high-speed railway bridges under earthquakes is the world’s first experimental equipment that can replicate the performance of trains running on bridges under earthquakes and extreme states of train derailment. It has completed more than 500 seismic tests of trains running on bridges. This technology has provided a crucial experimental platform for revealing disaster mechanisms, proposing control indicators, developing anti-seismic products, and revising national and industry standards. This patented technology has been implemented, and the large-scale scientific instrument developed as a result has a total investment of more than 60 million yuan. It has won the 2022 China Patent Excellence Award.

Schematic diagram of the patented technology “Seismic Safety Test System for Trains Running on High-Speed Railway Bridges Under Earthquakes”

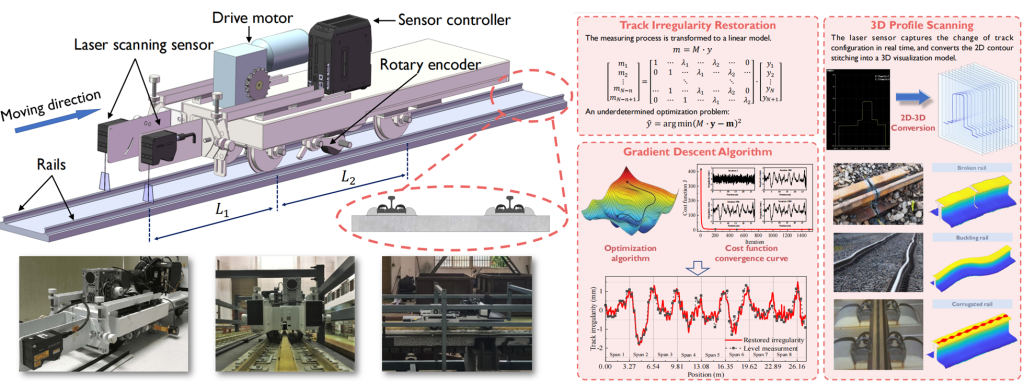

The patented technology “Laser Profile Scanning-based Track Irregularity Measurement Device and Method” mainly solves the problem of accurate measurement of track irregularities. Track irregularity is a key basic data that affects the running performance of high-speed trains. For the 1/10 scale model of the seismic safety testing system for trains running on high-speed railway bridges, the research team developed a technology that can achieve intelligent three-dimensional profile scanning. This technology can achieve precise measurements of track irregularities at a level of 0.01mm and in three dimensions, using techniques such as adjusting the wheelbase of the test vehicle and gradient drop. This patent has been implemented and provides crucial basic data for testing the performance of trains running on bridges under earthquakes.

Schematic diagram of the patented technology “Laser Profile Scanning-based Track Irregularity Measurement Device and Method”

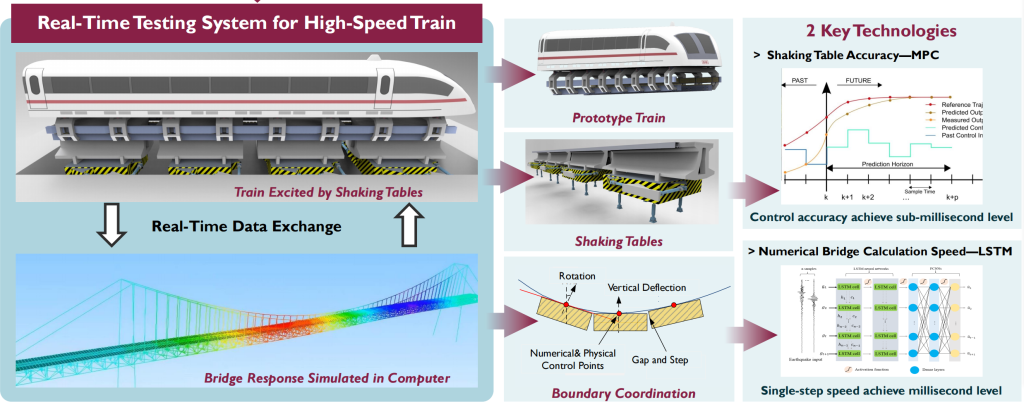

The core difficulty that the “Real-time Simulation Test System for High-Speed Railway Trains Running under Earthquake Action” patent solves is how to realize indoor full-scale experimental research on the safe running of high-speed railway trains under earthquake conditions and how to realize indoor full-scale experimental testing of 400 km/h speed wheel-rail and 600 km/h speed level high-speed maglev trains. This patent provides an innovative solution for full-scale indoor experimental technology for testing seismic extreme disasters and higher-speed train operation through the number-object integration hybrid testing technology between the “numerical” track and the “test” train. It solves many critical technical problems like millisecond-level real-time computing for large-scale numerical models of track-bridge system, millisecond-level latency control of six-degree-of-freedom eight-formation hydraulic servo system, and high-precision coordination between wheel-rail contact and maglev-rail number-object boundaries. The invention patent has been successfully implemented with the support of CRRC Qingdao Sifang Co., Ltd. The total investment in the equipment was approximately 160 million yuan, and the world’s only testing platform for assessing the performance of trains running on high-speed maglev bridges at a speed of up to 600 km/h was developed.

Schematic diagram of the patented technology “Real-time Simulation Test System for High-Speed Railway Trains Running under Earthquake Action”

(First Reviewer: Han Yan, Second Reviewer: Deng Haodi, Third Reviewer: Wang Jianxiang)

Source: School of Civil Engineering Author: ——

Source link: https://news.csu.edu.cn/info/1002/155672.htm